Feed Strategy, June 9, 2023

Marc Perel

Andritz Feed & Biofuel and Adisseo share their guidelines for adding liquid micro-ingredients at the main batch mixer.

How to best apply liquid feed additives in batch mixers

Andritz Feed & Biofuel and Adisseo share their guidelines for adding liquid micro-ingredients at the main batch mixer.

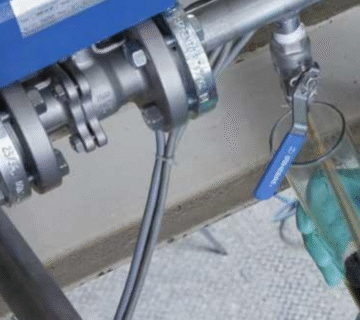

Source: Courtesy Andritz

rom reception to the application point in the mixer, following good design, operation and maintenance practices leads to the successful addition of liquid micro-ingredients. Recent tests conducted at two separate European feed mills by feed additive producer Adisseo and feed equipment manufacturer Andritz Feed & Biofuel illustrate this statement.

Designing the right application

Even when feed mills adhere to manufacturing best practices, each facility is unique. Therefore, when installing micro-liquid application equipment, the following needs careful consideration:

- Current and future volumes of production

- Type of feed

- The mixing lines to be equipped, including existing equipment

- Space availability

Climatic conditions, quality standards and dosage principles, i.e. flowmeter or weighing scale, vary significantly from region to region. Whether mechanical, electromagnetic or mass, the flowmeter must be located close to the mixer with easy and direct access. A calibration valve must be located after the flowmeter to verify the dosed quantity. The pump must be located close to the storage tank and the on/off valve must be as close as possible to the mixer.

Finally, piping must be installed so that gravity reduces after-run or leakage into the mixer. Each of these factors ensures that the correct micro-ingredient is dosed every time.

Spraying accuracy

Spraying is the most critical step in achieving proper application and homogeneity of liquid additives. To ensure accuracy, the following is necessary:

- Obtaining the correct size droplets

- Maintaining sufficient spraying time

- Spraying directly on the feed

- Avoiding after-run and blockage of nozzles

Spraying pressure is critical and should be between three to five bars.

The following will ensure these results:

- The correct nozzles flow pattern: flatbed or full cone

- The correct number, location and size of nozzles for applying the liquid additive across the mixer’s width

- The angle of the spray, the distance between nozzles, and the surface of the feed must all be considered

- Spray should not make contact with the sides of the mixer, shaft and paddles, and liquid sprays should not overlap

If there is a risk of dripping, there is an option to place a solenoid or anti-return valve before each nozzle and vary the number of injection points when quantities differ significantly from one batch to another. Another option is using compressed air to flush the manifold from the on/off valve to the mixer. Flushing this part of the pipe reduces after-run and clears out ingredients that can solidify and block the line.

Mixing serves dual purposes: mixing dry particles and dispersing liquid over those particles. Every mixer has its minimum dry mixing period, which must be met. Every liquid ingredient application benefits from a longer and finer spray to obtain a suitable recovery and homogeneity. Therefore, the available cycle time should be used to optimize the spray period. Additionally, the spray sequence should overlap the dry mixing time, so that line capacity is always maintained. The mixing diagram precisely defines these sequences.

Being in control of these steps is extremely important.

The shaft must turn continuously during filling and discharge. The mixing period begins when the mixer inlet is closed, and the last solid ingredients have been added. Fats and oils should not be introduced too early as they reduce the effects of mixing (agglomeration). However, water-based liquids like organic and amino acids and enzymes can be sprayed earlier.

Assessing quality

The quality of the liquid application is assessed using a test similar to dry mixing assessments. First, following a defined protocol, 10 samples are taken from the mixer’s discharge. Then, the concentration of active molecules in each sample is analyzed.

Two quality parameters are calculated:

- Homogeneity: obtained by calculating the coefficient of variation (CV) in the samples. The CV is the ratio between the standard deviation and the average and should be <10%, an industry standard.

- Recovery rate: calculated by dividing the average concentration by the expected concentration. Results should be close to 100%, with an acceptable range of between 90% and 110%.

This test is performed during equipment commissioning but should also be included in a quality assurance (QA) program with expected variations.

Monitoring & maintaining equipment

Maintenance of the application system includes:

- Cleaning intake filters (six months)

- Emptying and cleaning the bulk tank (five years)

- For the dosage:

- Calibration tests for scale or flowmeter (six months)

- Cleaning nozzles and mixer (as required)

- Cleaning the control cabinet

- Verification of electrical connections (annually)

Study of liquid application in two European feed mills

In July and August 2022, tests on homogeneity and recovery were conducted in two feed mills, using liquid methionine (OH-methionine) as a model. The feed mills, one located in the Czech Republic and the other in the United Kingdom (U.K.), applied this additive in an Andritz OptiMix batch mixer. Trials were performed under standard production conditions where OH-methionine was sprayed onto feed during mixing, and samples were extracted on the outlet conveyor. The Adisseo CARAT lab analyzed 10 samples from each facility for OH-Methionine quantification.

The U.K. feed mill produced a batch size of 4.018 kg, with an inclusion rate of 4.7 kg/t OH-methionine, equivalent to 18.8 kg. The dosing report revealed an actual weight of 18.7 kg, within the accepted tolerance. The results conform with a recovery rate of 94% and a CV of 2% – outstanding results.

In the U.K. feed mill study, the recovery rate was 94% with a CV of 2%. (Source: Adisseo)

On the other hand, the Czech feed mill produced a batch size of 1.917 kg, with an inclusion rate of 4.4 kg/t OH-methionine, equivalent to 8.433 kg. The dosing report revealed an actual weight of 8.430 kg, which also conforms. However, these results are only considered acceptable, as the recovery rate was 90% and CV was 8%.

In the Czech feed mill study, the recovery rate was 90% with a CV of 8%. Sample No. 4 had a significantly higher concentration, affecting the final figures. (Source: Adisseo)

Factors that may have affected the results:

- The flowmeter was calibrated four months earlier during a planned QA assessment and considered reliable.

- The dosage analysis revealed a deviation of less than 5 kg per day.

- No inventory analysis was available, but a slight overstock was reported.

- During the trial, the on/off valve on the mixer might have been closed early, keeping some of the additives from reaching the feed, causing a low recovery.

In the Czech study, sample No. 4 has a significantly higher concentration. Without this value, the CV would improve to 5% with a recovery of 88%, but there is no objective reason to discard the sample.

The conclusion is to continue to evaluate and see if the deviation reoccurs or was simply a coincidence, proving further support for a QA program to be established and executed regularly.

Key takeaways

Appropriate equipment must be selected, sized, configured, installed and maintained. Additionally, when design, operation and maintenance guidelines are accurately followed, the application of liquid additives is more predictable.

Finally, evaluating the homogeneity and recovery of a liquid additive – in this case, liquid methionine – via a reliable test is the best way to ensure correct application and implement corrective actions, if necessary, as illustrated in the tests above. Feed millers have many facets to manage, so it is essential to have trusted suppliers supporting you to continue operation.